Introduction

Reducing traceability to a mere CSR issue is a common — and costly — mistake.

Of course, a structured approach helps meet regulatory requirements and provide the guarantees consumers expect. But stopping there means underusing a tool with far greater potential.

In reality, traceability goes far beyond documenting product origins or collecting certificates.

It provides unique access to a valuable asset: supplier data. And when that data is properly structured, verified, and used over time, it becomes a real lever for operational performance — especially when it comes to quality.

Why? Because strengthening traceability isn’t just about enriching your product database.

It’s about building a detailed map of who does what, where, with what processes, and on which batches.

It’s about moving from passive documentation to active knowledge of your supplier network.

And that knowledge is what allows you to better identify risks, define expectations more clearly, and anticipate defects before they impact your margins.

In other words: quality isn't only built on your control lines. It’s shaped upstream — in the way you manage your supply chain.

And when used wisely, traceability is one of the most powerful tools you have to do just that — provided you know how to activate it effectively.

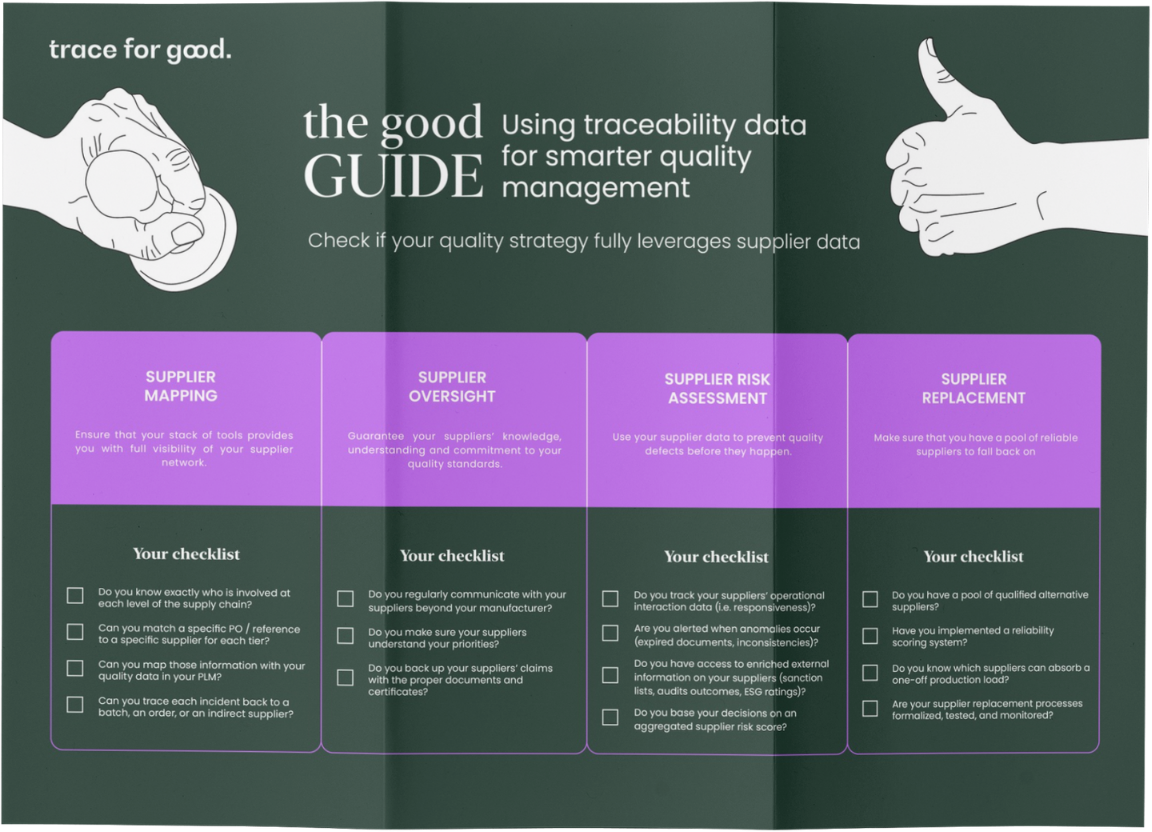

From mapping your supply chain to proactively identifying at-risk suppliers, here are four key levers to turn traceability into a true driver of quality.

1. Use your supplier data to map your network beyond Tier 1

You receive an order and discover a quality defect. Your immediate reaction? Act fast to secure the next deliveries and limit the impact on your current collection. And your suppliers? They’re your garment makers and like 80% of brands, you have no visibility beyond that. Not to worry though, they'll handle it.

But let’s take a step back. If you don’t know exactly who’s involved beyond your Tier 1 supplier, or if you only communicate through agents, can you truly address the root cause of the issue? By constantly reacting to emergencies, you risk treating the symptom without ever resolving the underlying problem.

And the essence of a long-term quality strategy requires moving beyond ‘reacting to defects’ to ‘understanding where they come from’ - and why they keep happening.

But to do that, one step is essential: mapping your entire supplier network.

This means going beyond direct suppliers to trace all the way back to production sites, raw materials, and subcontractors. Without this level of visibility, it's nearly impossible to assign responsibility, prioritize corrective actions, or engage the right people — yet those are all critical to driving long-term improvement.

In practice, mapping your supplier network allows you to:

- Connect each product, order, and batch to the suppliers actually involved in its production — including beyond Tier 1 suppliers.

- Link this information with your existing systems (PLM, ERP, etc.) to streamline operational management — without creating new silos.

- Quickly identify the root cause of a defect, whether it comes from a non-compliant material, an uncontrolled production site, or an unapproved subcontractor.

The key? Relying on a tool that fully integrates with your internal ecosystem. For mapping to be truly actionable, the solution you choose must be interoperable with your internal systems — PLM, ERP, PIM. And most importantly, it should go beyond network visualization by enabling clear, structured communication of your requirements throughout the entire supply chain.

2. Structure the oversight of your indirect suppliers with a dedicated tool

You’ve now identified the root causes of your quality issues and gained clear visibility over your entire supplier network. That’s a major step forward — but it’s only the beginning. In most cases, quality deviations aren’t the result of bad intentions. They often stem from a lack of structure and clarity.

Upstream subcontractors, especially those working with your garment manufacturers, often have only a partial understanding of your expectations. Without clear guidelines, and under cost pressures driven by sourcing teams, they make decisions that may compromise final product quality.

To prevent these deviations from recurring, it becomes essential to create a clearer framework across the entire chain — by defining shared standards, communicating best practices, and holding each link accountable. But this requires a careful balance: your dyers and weavers aren’t your direct partners, they’re your manufacturers’ suppliers. In other words, bypassing your manufacturer to intervene directly may damage the commercial relationship, or be perceived as undermining your partners' authority.

The challenge is to establish a structured framework without overstepping responsibilities — by equipping your finished goods suppliers to relay, apply, and monitor your requirements within their own supply chains.

An effective traceability platform helps you meet both objectives: structuring how your quality standards are shared, while preserving smooth, respectful collaboration with your suppliers. It acts as an operational intermediary — streamlining onboarding, communication, and compliance tracking without overcomplicating internal workflows or upsetting established dynamics.

Practically speaking, managing supplier relationships through a dedicated platform enables you to:

- Maintain continuous, multilingual communication, through interfaces tailored to your suppliers’ real-world constraints. They can ask questions at any time and get answers in their own language, in real time.

- Collect and verify compliance documents over time, by requesting certificates, attestations, or quality-related documentation directly. These materials support supplier claims and strengthen the reliability of your product data.

By structuring responsibilities and interactions in this way, you empower your direct suppliers to effectively pass on your expectations — with no disruption, no ambiguity, and no information lost along the way. You're no longer just defining standards from the top down: you’re creating the practical conditions for those standards to be understood, implemented, and maintained on the ground — right through to the last subcontractor involved in your production.

3. Analyze your collected data to identify high-risk suppliers faster

You've now mapped your supplier network and engaged your partners in a structured approach. You're in a position to act effectively when a quality issue arises. But here’s a key question: what if you could prevent these issues before they even occur?

A visible defect is often just the tip of the iceberg — the symptom of an existing imbalance. Weak signals usually appear earlier: unusually slow response times, missing or inconsistent documents, irregular communication, or an erratic track record.

The real problem might not be a lack of information if your teams are already collecting data, but rather the absence of structured consolidation. And it’s precisely this consolidation that enables you to build a risk score incorporating quality indicators, allowing you to spot vulnerabilities early, before they escalate into operational problems.

To move from reactive handling to proactive risk management, several indicators can be consolidated into a dedicated supplier risk scoring model. This scoring framework helps objectify your decisions and flag risky situations before any defects appear.

Signals to track might include:

- Operational interaction data, such as response times, document completeness, and update frequency — all valuable clues about a supplier’s long-term reliability.

- Detected anomalies, like an inconsistent or expired certificate, a questionable document, or sudden behavioral changes over time.

- External enriched data, including location, geopolitical risks, or third-party sources (sanctions lists, audit outcomes, ESG ratings), which help refine your understanding of the supplier’s overall context.

There are several ways to build this scoring system: manually, through in-house development, or via a traceability platform. The latter offers a more scalable, flexible approach by automatically consolidating these signals, at the supplier or product level. This enables you to go beyond generic supplier evaluations and pinpoint risk areas based on product type, material, or production site.

By centralizing these inputs into a dynamic, shareable score, you shift from defect management to proactive quality and risk control. You gain visibility, reliability, and the ability to act before issues become critical.

4. Build a pool of reliable suppliers to fall back on when performance drops

You’ve identified your highest-risk suppliers — those whose shortcomings, even if not yet visible, will inevitably impact the quality of your products… and your margins. You know that asking your agents or manufacturers to switch partners is no small matter. Even a single substitution can destabilize your supply chain and create internal or external friction.

This puts you in a difficult position: should you maintain the relationship by putting safeguards in place? Or consider a replacement, with all the risks that entails?

In practice, many organizations choose to remain in limbo — tolerating subpar performance for lack of a clear alternative. And yet, that alternative often already exists… within your own supplier base. Some partners you’re already working with — reliable, committed, and proven — may very well have the skills and capacity to take over a critical production line.

But how can you identify these alternatives without wasting time or introducing new risks?

This is where a well-structured traceability platform becomes essential: by centralizing supplier data and making available capacities visible across your network, it becomes a powerful decision-making tool.

In practical terms, it enables you to:

- Build and maintain a pool of qualified suppliers, with up-to-date profiles, performance history, and proven operational readiness.

- Track supplier reliability over time, using documented incidents, performance data, and real-world feedback.

- Manage transitions smoothly, with immediate access to critical documents (technical specs, contracts, quality validations, etc.).

In short, it turns a complex and risky decision into a controlled process — where each step is anticipated, documented, and aligned with your operational goals.

Conclusion

For a long time, product quality was managed downstream — through inspections, audits, and corrective actions. Not because quality teams believed this was the most effective approach, but simply because they lacked upstream data to act differently.

Yet in today’s increasingly complex supply chains, this reactive model no longer holds up.

Improving quality sustainably starts with understanding where it comes from.

The most advanced brands know this: quality performance doesn’t just depend on what happens at the factory or on the inspection line. It hinges on the ability to see, structure, and secure every link in the chain — from raw material sourcing to the last subcontractor involved in production.

That’s where traceability comes into play. Not as a box-ticking compliance tool, but as a foundational approach — one that transforms scattered data into actionable insights and operational levers.

When thoughtfully designed and well integrated, traceability becomes a powerful backbone for quality management. It aligns stakeholders, informs decisions, and enables you to anticipate risks rather than just respond to them.

And over time, it helps your brand shift from reactive firefighting to a strategic, collaborative, and continuous quality management approach.

.jpg)

.png)

.png)